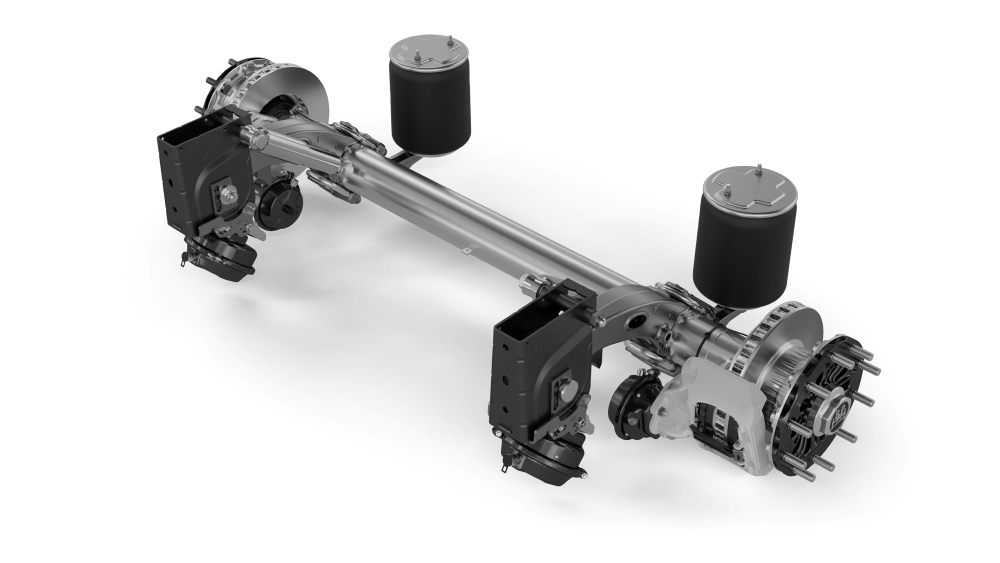

Rigid axles

For over 100 years, BPW customers have favoured the company's expertise: for applications from 5.5 t to 20 t, BPW offers a wide variety of axles that can be combined with disk and drum brakes as well as air or mechanical suspension systems.

No chance for rust and stone impact due to the cataphoretic dip-coating based on zinc-phosphating.

The standard DIN ISO tapered roller bearings contribute to the long service life of BPW rigid axles since the stepped bearing size allow the hubs to be easily removed.

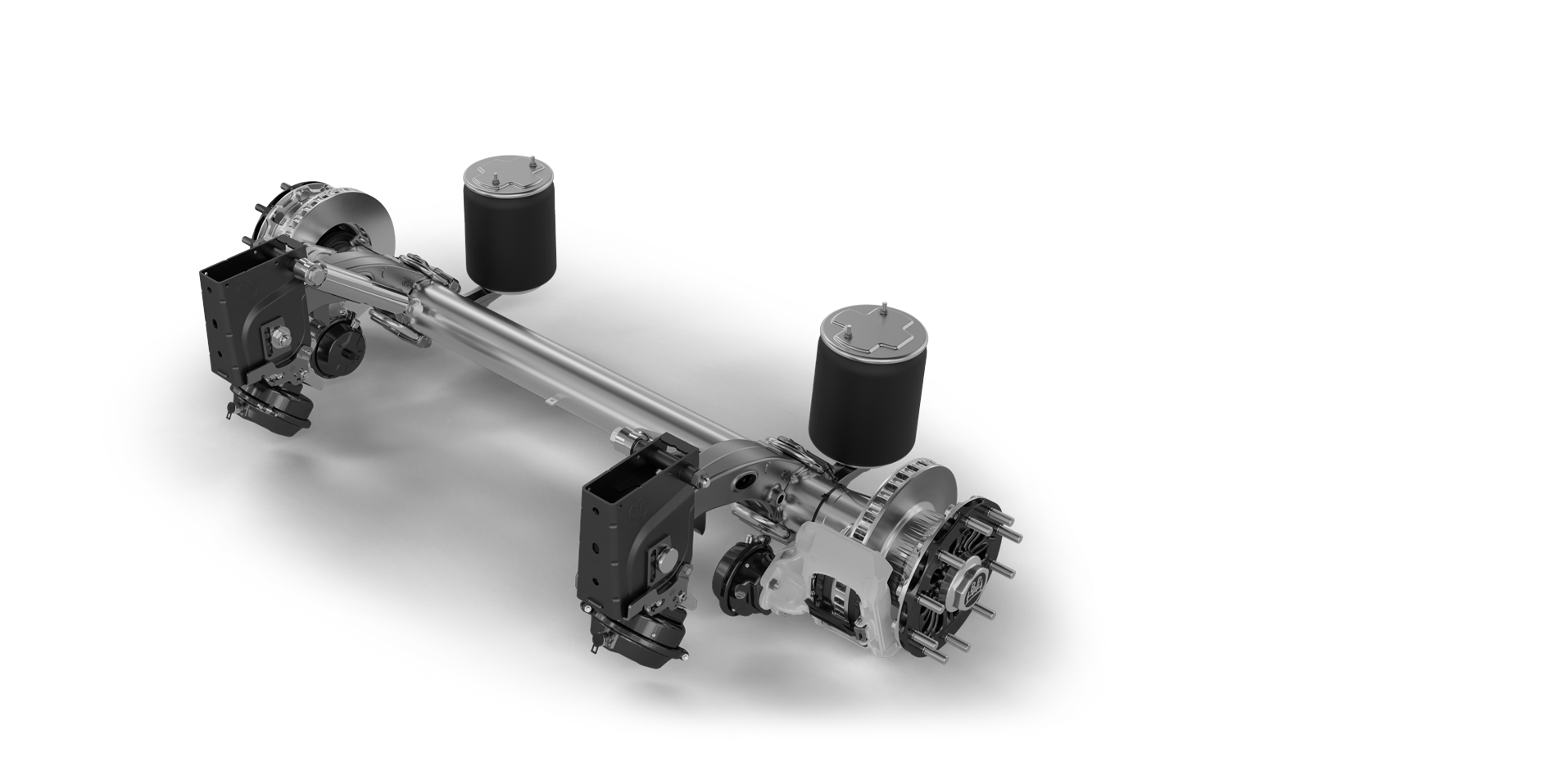

Starrachse

For every application

For over 100 years, BPW customers have favoured the company's expertise: for applications from 5.5 t to 20 t, BPW offers a wide variety of axles that can be combined with disk and drum brakes as well as air or mechanical suspension systems.

Long service life

No chance for rust and stone impact due to the cataphoretic dip-coating based on zinc-phosphating.

Service-friendly maintenance

The standard DIN ISO tapered roller bearings contribute to the long service life of BPW rigid axles since the stepped bearing size allow the hubs to be easily removed.

Features and benefits

- For axle loads up to 20 t

- Versions with air or mechanical suspension

- Versions with disc or drum brake

- With (mounted) BPW brake cylinders

- Wheels with or without offset

- Single or twin tyres

- Wheel sizes from 12 to 24 inches

- Bolt alignment or spigot alignment

- For disc wheels (steel or aluminium) or spider wheels (TRILEX)

- ABS can be retrofitted

* All axles also have cataphoretic dip-coating and zinc-phosphating at inaccessible points such as in cavities to provide optimum protection against corrosion.

Product details

Hard-working and lightweight

BPW rigid axles are the strong backbone for your trailer. They are rugged, have an extremely high load capacity and are competitively lightweight. For ECO Plus 3, our designers have succeeded in reducing the unladen weight of each axle by up to 25 kg. For you this means increased payload for greater efficiency.

The single-part axle beam is the key

The most important feature of a rigid axle is the connection between both ends of the axle by means of a single-part axle beam: If the position or angle of one wheel changes, e.g. during one-sided spring compression, the other wheels will be forced upwards. This also applies to changes in camber and toe-in. The axle transfers the static, dynamic and vertical wheel loads, longitudinal forces acting in the direction of travel (e.g. caused by braking) as well as transverse forces which occur during cornering, for example.

Rigid axles: A quick look at how they work

The spindle of the axle beam holds the wheel bearings and therefore the hub to which the wheel is mounted by means of the wheel studs. Depending on the brake type, the brake disc or brake drum is connected to the hub. The brake anchor plate is welded onto the axle beam and provides the connection to the brake. The brake caliper is bolted on disc brake axles. On axles with drum brakes, it holds the brake shoes. The axle mounting joins the axle to the suspension. The wheels, axle and suspension form the running gear and are mounted on the chassis of the trailer or the semi-trailer.