Authors: Tobias Zeller, Kühnert Marius, Schmitt Michael, Cujic Patrick, Prof. Martin Doppelbauer (all Elektrotechnisches Institut am Karlsruher Institut für Technologie), Dennis Bank (Institute of Mechatronic Systems)

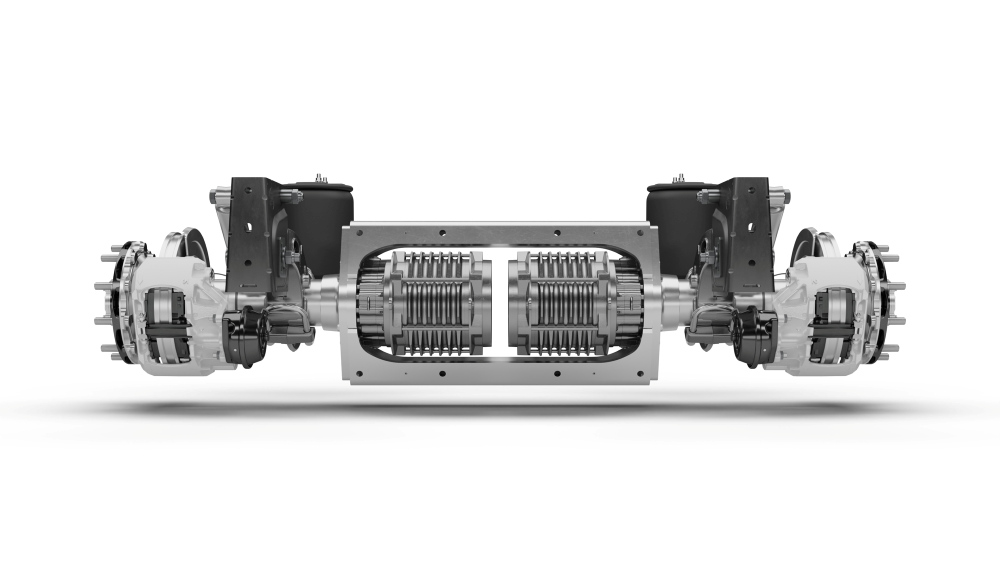

This paper deals with the concept development of a gearbox design for optimum brake energy recovery of a truck trailer with the use of a synchronous reluctance machine. Planetary and or spur gears are selected on the basis of a utility analysis. Based on this, a computer-aided gearbox design tool is developed, which generates an ideal gearbox concept for brake energy recovery on the basis of a motor/generator characteristic and a drive cycle. The optimal gear ratio as well as possible gearbox topologies and gearing are calculated automatically. The possible gearbox topologies are 1- to 3-stage gears consisting of planetary or spur gear stages, and in the case of multi-stage gearboxes, permutations of them. In addition, the configuration of axle drive (one generator with differential) or wheel drive (two generators) can be specified as a starting condition. A joint integration and design process of the gearbox and generator offers many advantages such as compactness, easier handling and faster calculation. An optimization criterion is used to select the appropriate gear unit. As a result, the user receives the optimum gearbox topology, the distribution of the total gear ratio among the stages and the gear geometry, as well as further information on mass, costs, installation space and energy yield. Finally, the gear concept synthesis is validated using analytical equations and commercial gear design software, such as KISSsys and KISSsoft. For this reason, a combination of real driving data determined in VECTO and the analytical calculation of the gearbox generator system is used.

The authors would like to thank the project leader "Deutsches Zentrum für Luft- und Raumfahrt e.V." (DLR) for leading the "RekuTrAx" project (project number 01MV22018) and the "Federal Ministry for Economic Affairs and Climate Action"(BMWK) for funding.