BPW turntables have got the answer

BPW turntables are characterised by a doubled row of bearings to guarantee optimal distribution of the axial and radial forces that arise.

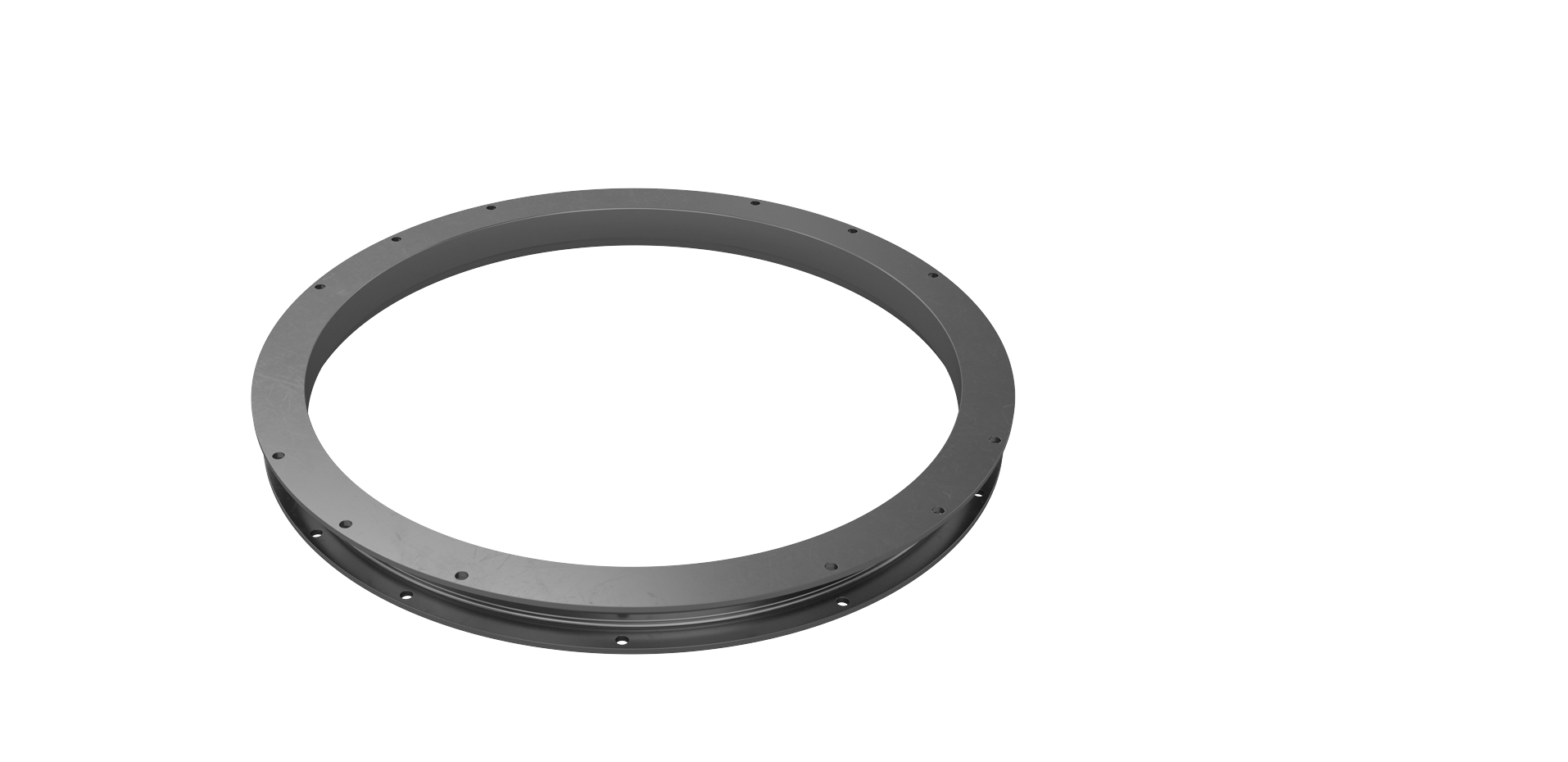

The turntable sections made from high-strength steel are cold formed, butt welded and calibrated. As a result, the turntables can cope with extremely challenging conditions.

The bearing race is supported under load by the double row of ball bearings which are provided with long-lasting protection against dust and dirt by a labyrinth seal. BPW turntables thus guarantee a minimum of down time combined with long service life.

Double is better

BPW turntables are characterised by a doubled row of bearings to guarantee optimal distribution of the axial and radial forces that arise.

Top quality

The turntable sections made from high-strength steel are cold formed, butt welded and calibrated. As a result, the turntables can cope with extremely challenging conditions.

Long life expectancy

The bearing race is supported under load by the double row of ball bearings which are provided with long-lasting protection against dust and dirt by a labyrinth seal. BPW turntables thus guarantee a minimum of down time combined with long service life.

Features and benefits

- Permitted axial load 5 t to 30 t

- Choice of drilled or undrilled

- Optimal distribution of the axial and radial forces that arise due to double ball bearing race

- Turntable sections made of cold formed, butt welded, calibrated, high-strength steel

- Protection of the turntable interior against dust and dirt through labyrinth sealing

- Wear-resistant due to low roll depth of the axial ball race and increasing hardening of the ball race under stress

Product details

For turntable drawbar trailers, the rigid front axle of the trailer is steered using a pivot mounting with a turntable and drawbar. The turntable provides the connection between the vehicle frame and the pivot mounting.

BPW turntables generally have two rows of ball bearings. This special design ensures better and more wear-resistant force transmission and thus longer service life.

Optimum force transmission

- BPW turntables have one axial and one radial ball race between the upper and lower rings.

- The axial loads acting on the turntable are absorbed by the large ball race in a vertical direction.

- The horizontal forces are absorbed by the smaller radial ball race.

- The torque loadings, caused by braking and centrifugal forces, are absorbed in the interplay between the two ball races.

- The radial ball race retains the upper and lower rings in place.

Absolute functional reliability

- The design principle guarantees the greatest possible safety because the acting axial and radial forces are separately transmitted onto the two ball races.

- The materials and production processes are carefully selected to deliver the highest quality. The turntable sections are made of cold formed, butt welded, calibrated, high-strength steel. As a result, the turntables can be used even under extreme conditions.

Economy through long service life

BPW turntables guarantee a minimum of down time due to their long service life.

- The ball race is secured under load by the axial ball race.

- The space inside the turntable is provided with long-lasting protection against dust and dirt by a labyrinth seal.

- The sum of all these advantages ensures reliability, freedom of movement and the highest possible service life.

See the BPW turntable brochure for more information about the mechanical design as well as installation and maintenance.